Jinan Factory 1325 6090 Wood Cutting Machine Atc Wood CNC Router

Basic Info

| Model NO. | M2-1325C |

| Range of Spindle Speed(r.p.m) | 0 - 24000 Rpm |

| Number of Axes | 3 |

| No. of Spindles | Single |

| Working Table Size(mm) | 2500*1230 |

| Spindle Motor Power(Kw) | 9 |

| Power (Kw) | 22 |

| Control System Brand | Syntec |

| Key Selling Points | Easy to Operate |

| Machinery Test Report | Provided |

| Table Structure | T-Slot Vacuum |

| Transmission | Tbi Ball Screw |

| Inverter | Taiwan Delta Inverter |

| Motor and Driver | Japan Yaskawa Sevor Motor |

| Spindle | Italy Hsd Air Cooling Spindle |

| Applicable Industries | Manufacturing Plant, Construction Works |

| Transport Package | Standard Export Woodencase |

| Specification | 2250*3300*1700 |

| Trademark | GONGDA |

| Origin | Jinan, Shandong |

| HS Code | 84659900 |

| Production Capacity | 200 Sets/Month |

Product Description

3Axis Milling Engraving Drilling CNC Router With Linear ATC Tool Changer Magazine

Designed with linear type auto tool changer, it automatically changes 6 sets of tools without the need for manual tool change, which greatly improved processing efficiency. Smart industrial controller-enabling this product to accomplish multi-layer 3D job,cutting,engraving,milling,all at ease.Detailed Photos

Automatic linear type tool changer unit 8 pcs

The machine adopts linear tool magazine, standard equipped with 8 tools, and the number of tool magazines can be selected according to the needs, which can effectively reduce the tool change time and improve work efficiency.

ATC High speed spindle router

1.Powerful 9 KW automatic tool change Spindle, 24000rpm, Powerful twisting force and fast processing.2.it is suitable for heavy cutting, milling etc.,it will keep the surface of work pieces very smooth.

Taiwan syntec control systemUser-friendly interface, easy operation and fast response.After-sales service points all over the world.

1.CAD can be used to import data, quick and convenient operation2.can match user production design management software3.without independent input data, intelligent processing list4.one import operation, continuous processing completed.

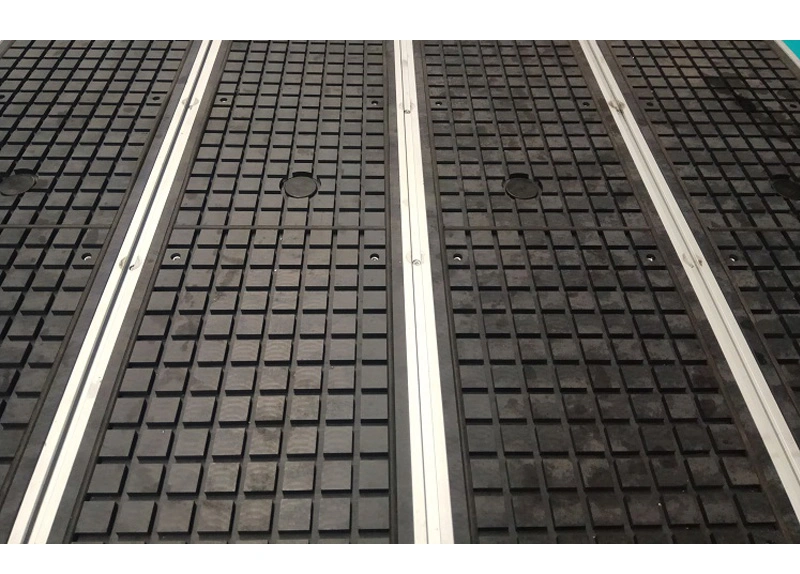

T-slot and vacuum table

The table top adopts T-slot and vacuum table combination, can strongly adsorb different areas of materials, also can fix different shapes of materials, flexible and convenient.Product Parameters| Description | Parameter |

| Model | ATC 1325 Woodworking Machines |

| X,Y,Z Working Area | 1230*2480*180/280 mm |

| Table size | 2500*1230mm |

| Table structure | T-slot vacuum table |

| Frame | New type thicker and bigger heavy duty welded frame and gantry |

| Transmission | X/Y rack and pinion drive,Z ball screw drive |

| Spindle | 9.6kw Italy HSD air cooling spindle |

| Spindle Speed | 24000r/min |

| Drive Motors | Japan YASKAWA servo motors and drivers |

| Inverter | Taiwan Delta Inverter |

| Working Voltage | AC380V, 3Ph, 50Hz |

| Travelling speed | 40m/min |

| Working speed | 18m/min |

| Tool magazine | Linear 6/8 slots |

| Controller system | Syntec |

Application

Sample & Application:WoodFurniture Industry: Wave Plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates,cupboarddoors, interior doors, sofa legs, headboards and so on.Advertising Industry: advertising identification, sigh making, Acrylic engraving and cutting, crystal word making,blaster molding,and other advertising materials derivatives making.Die Industry:A sculpture of copper, aluminum, iron and other metal molds, as well as artificial marble, sand,plastic sheeting,PVCpipe, wooden planks and other non-metallic mold.Relief Sculpture and 3D Engraving & Cylindrical object.Exhibition

Company Profile

Company Profile

Jinan Gongda CNC technology is founded in 2019, located in Jinan,Shandong province ,where is the biggest woodworking machine industry area in north of China. GONGDA CNC is a company specializing in the development and manufacture of automated woodworking equipment of different specifications,laser engraving and cutting machine,Our machine are widely used in panel furniture, custom cabinet wardrobes,solid wood furniture and metal processing fields.Our quality standard positioning is synchronized with Europe and the United States. The whole line adopts standard international brand parts, has strict process quality inspection. We are committed to providing users with stable and reliable equipment for long-term industrial use.Our machine are exported to more than 30 countries and regions, such as United States, Russia, Germany, the United Kingdom, Australia, Canada, Belgium,etc. In the future, GONGDA CNC will keep focusing on research, development, and manufacturing panel furniture machines, welcome more friends to know us and become partners to create a bright future with each other.

Our TeamOur Workshop

Packaging & Shipping

Packaging Details:

1.The innermost layer is EPE pearl cotton film package.2.The middle layer is wrapping up with environmental protection material .3.And the outermost layer is winding up with PE stretch film.4.They're very environmentally friendly.5.If you need a wooden box, we will make a wooden box.FAQ FAQDear, in order to recommend the best suitable machine with the best quality and price for you, please kindly contact me with below questions, our professional services will satisfy you! Q1. I need a CNC router,can you give me some suggestions?

A: Sure,we will give suggestions of the most suitable machine.Before that,we need know some information.such as effective processing area,materials,etc.,to determine the main parameters. Q2:Which kind of materials can be processed on this machine?

A:Wood,mdf,acrylic,glass,plastic,foam,aluminium,and almost all kinds of non-mental materials. Q3: How should I pay for my order?

A: You need to pay 30% as prepayment at first, then we will start to make production.when the machine is completed,we will send pictures or videos to you,and then you need to pay the balance.we will ship the machine to you after we receive your full payment. Q4: How about the warranty?

A:One year warranty. Spare parts are not included. We suggest u buy some spare parts in stock. Q5:How long is the delivery time?

A:For standard machines,it will be 15 days;For non-standard machines and customized machines according to clients' specific requirements,it will be 15-30days. Q6: What should I do when I have some problems or questions?

A: Pls don't hesitate to contact us, we will reply u ASAP. Q7. Quality Control: A:The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before being out of factory.The testing video and pictures will be available before delivery.