Portable Auto Focus CCD 20W 30W 50W 60W 100W Jpt Raycus Mopa UV Galvo Fiber Laser Color Printing Marking Machine for Metal Plastic Glass Logo Engraving

Basic Info

| Model NO. | YML-FT |

| Laser Wavelength | Fiber Laser |

| Laser Classification | Fiber Laser |

| Type | Optical Fiber Laser Marking Machine |

| Marking Method | Scanning Marking |

| Laser Power | 20W 30W 50W 70W 100W |

| Laser Source | Jpt Raycus Max |

| System | Ezcad |

| Machine Color | White |

| Scan Lens | Sino-Galvo 7110 |

| Weight | 100kg |

| Marking Speed | 7000mm/S |

| Application | Metal Jewelry Ring Glass Plastic Aluminium |

| Laser Type | Fiber Laser |

| Engraving Area | 110*110mm , 200*200mm , 300*300mm |

| Color Marking | Yes |

| Cutting Function | Yes |

| Rotary Diameter | 80mm 100mm 120mm |

| Deep Engraving | Yes |

| Marking Precision | 0.01mm |

| Transport Package | Wooden Box |

| Specification | 80*65*145cm |

| Trademark | YVCHUANG |

| Origin | China |

| HS Code | 8456110090 |

| Production Capacity | 500 Sets/Month |

Product Description

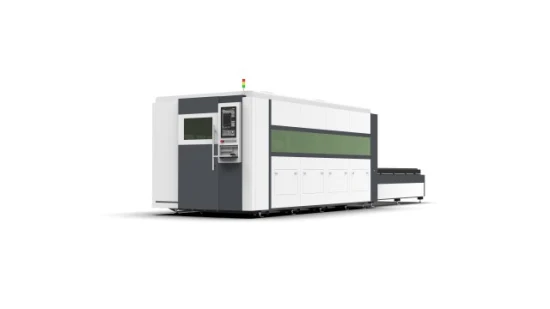

Application Industries: Fiber Laser Marking Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.Product Parameters

Features of Fiber Laser Marking Machine:1. Easy operation and quick installation, Software and computer will be sent with machine . Although you changed computer in future , you can also install software again . 2. Low Cost: high turnover ratio between electricity and laser, the whole machine power consumption is less than 500W, which is 1/10 of light pumping source laser.3. Free-Maintenance Operation: There is no need of any maintenance for laser, or cleaning the lens.4. Long Service Life: The laser metal engraving machine adopts laser diode as pumping source, the working hours can reach as long as 100,000 hours.

| Model | YML-FT |

| Marking area | 110*110mm(option: 200*200, 300*300 ) |

| Laser power | 20w / 30w / 50w / 100w |

| Marking speed | 7000mm/s |

| Minimum line width | 0.01mm |

| Cooling Type | Air Cooling |

| Laser lifespan | 100,000 hrs |

| Positioning Accuracy | ± 0.01 mm |

| Graphic format supported | PLT, BMP, DXF, JPG, TIF, AI, PNG, JPG, etc formats; |

EZ-CAD CONTROL SYSTEM

Adopts EZ-CAD control system, User friendly easy to operate,supporting PLT, BMP, DXF, JPG, TIF, AI, PNG, JPG, etc formats;SINO-GALVO SCANNERSINO-Galvo Scanner has compact design, high positioning accuracy, higher marking speed, and strong anti-interference ability. In the process of dynamic marking, the marking line has high precision, distortion free, power uniform; pattern without distortion, the overall performance has reached the international leading level in the field.

GOOD LASER SOURCE

Equipped with high quality fiber laser source from RAYCUS brand ,laser lifespan up to 100,000 hoursSamplesPackaging & Shipping

Our laser marking machine have passed European CE and American FDA certicates .

Company ProfileYvchuang Laser is one of the world's leading manufacturers of high-tech industrial laser solutions, dedicated to providing laser intelligent equipment solutions and enabling our customers in various branches around the world to become more efficient and competitive. With more than 15, 000 laser cutting systems in the market and a rapidly increasing global base, Yvchuang laser is in a favorable position to serve the international customer base, guaranteeing highest quality and shortest response times in already more than 100 countries. Our focus is on the innovation, continuous improvement and rapid development of technologies, all of which aim to increase efficiencies and flexibility, minimize costs while generating the highest levels of environmental friendliness and sustainability to our all benefit. We aim to provide key technologies and customized integration solutions for Industry 4.0 and smart factories, helping enterprises to make perfect use of the many opportunities arising in the digital age. The product range not only comprises of flat sheet cutting systems in various designs and dimensions, but also of laser tube cutting systems, CO2 laser cutting engraving machine, laser marking machine etc. With our focused, highly skilled and experienced R & D team and a perfectly equipped and trained systematic after-sales technical department, we truly provide customer-oriented service experience.