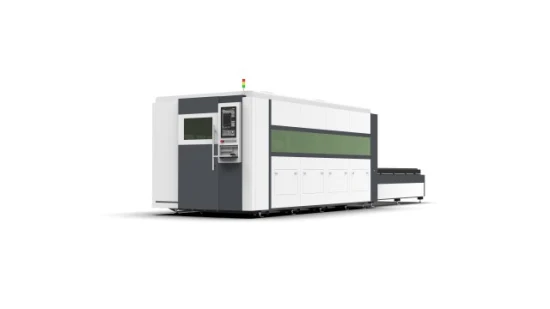

High Power 2000W Metal CNC Fiber Laser Cutting Machine for Metal

High Power 2000W Metal CNC Fiber Laser Cutting Machine for Metal I.Company Products Introduction:The company mainly prod;

Basic Info

| Warranty | Three-Year |

| Application | Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry |

| Cooling System | Water Cooling |

| Technical Class | Continuous Wave Laser |

| Applicable Material | Metal |

| Structure Type | Desktop |

| Laser Classification | Gaseous Laser |

| Laser Technology | Laser Control Fault Cutting |

| Laser Cutter Type | Fiber-Optic Laser |

| Cutter Wavelength | 1064 Nm |

| Frequency | 50Hz |

| Y Axis Travel | 2020mm |

| X Axis Travel | 4020mm |

| Maximum Empty Speed | 60m/Min |

| Z Axis Travel | 100mm |

| Transport Package | Wooden Package |

| Specification | 2000W |

| Trademark | EN-SOURCE |

| Origin | China, Zhejiang |

| HS Code | 845610009 |

| Production Capacity | 500 |

Product Description

High Power 2000W Metal CNC Fiber Laser Cutting Machine for MetalI.Company Products Introduction:The company mainly produces three types of products, including CNC turret punch press (servo type, hydraulic type, mechanical type), laser cutting machine (YAG and optical fiber), flexible processing production line in sheet metal industry, with more than 30 products. The products are widely used in cold stamping processing industry, such as electric control cabinets, kitchen equipment, lamps, lid making, tank production lines, instruments, solar water heaters, battery iron plates, architectural decorative plates, auto parts, metal furniture, mufflers, screens, etc.II.Laser Cutting Machine Photo:

III.Laser Cutter Equipment Main Configuration

| No. | Name | Origin and manufacturer name |

| 1 | Fiber laser cutting machine generator(2000W) | Rui Ke |

| 2 | Special laser cutting head (auto focus) | Shanghai Jiaqiang |

| 3 | Cuting machine bed (steel plate welding) | Self-produced |

| 4 | Beam | Integrated welding beam |

| 5 | Guide | Taiwan HIWIN |

| 6 | Reducer | France Motoly |

| 7 | Gear, rack | Taiwan K.H |

| 8 | Servo motor and driver | Japan Panasonic |

| 10 | Control cabinet | Self-produced |

| 11 | Low-voltage electrical appliances | Chint |

| 12 | Origin, limit switch | Swiss Carole |

| 13 | Cable | Flexible shielded cable |

| 14 | Transformer | Shenzhen Xinbei Ocean |

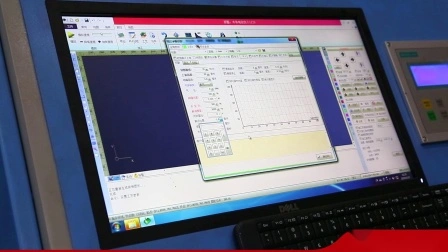

| 15 | IPC | Taiwan Advantech |

| 16 | Monitor | United States Dell |

| 17 | CNC system (including control software, height controller) | Shanghai company |

| 18 | Oil road | Electric oil pump |

| 19 | Gas circuit (proportional valve) | NNT |

| 20 | Chiller | Han Li |

Configuration 1 introduction:(1)The fuselage is welded 12mm carbon steel welded, after rigorous stress relief annealing heat treatment.

(2)More scientific design and high-strength steel-frame structure, which increase the fuse large strength more than 40% to prevent the machine from distortion during long time work. That can make sure the machines' stable and reliable working performance.

Configuration 2 introduction:Raycus lasers has higher electro-optical conversion efficiency, higher and more stable optical quality, stronger altitude stress-resisting capacity to ensure more stable and more sophisticated cutting, working life of 100,000 hours.

IV.Main Technical Parameters of Fiber Laser Cutting Machine

| No. | Device model | GX4020-2000W |

| 1 | Laser cutter type | fiber-optic laser |

| 2 | Laser working medium | optical fiber |

| 3 | CNC laser cutter wavelength | 1064 nm |

| 4 | Rated output power | 2000 W |

| 5 | Beam quality | <0.373mrad |

| 6 | X axis travel | 4020mm |

| 7 | Y axis travel | 2020mm |

| 8 | Z axis travel | 100mm |

| 9 | Effective cutting range | 4000×2000mm |

| 10 | Workbench axial positioning accuracy | ≤±0.05mm/m |

| 11 | Worktable repeat positioning accuracy | ≤±0.02mm/m |

| 12 | Maximum empty speed | 60m/min |

| 13 | Workbench maximum load | 2000KG |

| 14 | Phase | 3 |

| 15 | Power supply rated voltage | 380V |

| 16 | Frequency | 50Hz |

| 17 | Total power protection level | IP54 |

V.Cutting Metal Performance Table:

| Material | Thickness(mm) | Speed(m/min) | Power (W) | Auxiliary gas |

| Stainless steel | 1 | 35 | 2000 | air |

| 2 | 10 | 2000 | air | |

| 3 | 6.5 | 2000 | air | |

| 4 | 4 | 2000 | air | |

| 5 | 2.4 | 2000 | air | |

| 6 | 1.6 | 2000 | air | |

| 8 | 0.9 | 2000 | air | |

| 1 | 30 | 2000 | N2 | |

| 2 | 9 | 2000 | N2 | |

| 3 | 6 | 2000 | N2 | |

| 4 | 3.2 | 2000 | N2 | |

| 5 | 2 | 2000 | N2 | |

| 6 | 1.2 | 2000 | N2 | |

| 8 | 0.6 | 2000 | N2 | |

| Carbon steel | 1 | 9 | 2000 | O2 |

| 2 | 4.2 | 2000 | O2 | |

| 3 | 3.8 | 2000 | O2 | |

| 3 | 3 | 2000 | O2 | |

| 4 | 3.3 | 2000 | O2 | |

| 4 | 2.8 | 2000 | O2 | |

| 5 | 2.6 | 2000 | O2 | |

| 6 | 1.8 | 2000 | O2 | |

| 8 | 1.3 | 2000 | O2 | |

| 10 | 1.1 | 2000 | O2 | |

| 12 | 1 | 2000 | O2 | |

| 14 | 0.9 | 2000 | O2 | |

| 16 | 0.8 | 2000 | O2 | |

| Brass | 1 | 25 | 2000 | N2 |

| 2 | 7.5 | 2000 | N2 | |

| 3 | 3.5 | 2000 | N2 | |

| 4 | 1.8 | 2000 | N2 | |

| 5 | 0.8 | 2000 | N2 | |

| Aluminum | 1 | 30 | 2000 | N2 |

| 2 | 8 | 2000 | N2 | |

| 3 | 4 | 2000 | N2 | |

| 4 | 2.5 | 2000 | N2 | |

| 5 | 2 | 2000 | N2 | |

| 6 | 1 | 2000 | N2 | |

| 8 | 0.6 | 2000 | N2 | |

| 1 | 30 | 2000 | Air | |

| 2 | 9 | 2000 | Air | |

| 3 | 3.2 | 2000 | Air | |

| 4 | 2 | 2000 | Air | |

| 5 | 1.4 | 2000 | Air | |

| 6 | 0.8 | 2000 | Air | |

| Copper | 1 | 12 | 2000 | O2 |

| 2 | 4 | 2000 | O2 | |

| Galvanized sheet | 1 | 25 | 2000 | N2 |

| 2 | 9 | 2000 | N2 | |

| 3 | 4.5 | 2000 | N2 |

2.Installation and training: After the equipment is delivered to buyer factory, the supplier is responsible for the laser cutting machine installation, commissioning and delivery of the site on the demand side with the assistance of the demand side, and brings the necessary special tools and debugging tools. And the engineer will train operation and maintenance worker again. The training content includes:Laser safety protection common senseThe basic principle of laser and the structure of laser cutting machineOperating skills of control systemsEquipment operation and precautionsRoutine equipment maintenance, laser adjustment and spare parts replacement operation skillsThe training time is about 5 days3. Equipment acceptance: After the contract is signed, the supplier designs and manufactures the equipment strictly in accordance with the technical specifications of the contract. After the equipment is manufactured and manufactured, the demand side performs pre-acceptance on the equipment according to various technical indicators at the location of the supplier. After the equipment is installed and commissioned on the demand side, both parties conduct final acceptance of the equipment feasibility, stability and reliability according to the pre-acceptance standards.4. After-sales service: The company provides a two-year warranty and lifetime maintenance on the products purchased by the buyer. During the warranty period, the equipment is faulty and the machine parts are damaged (except for human factors and force majeure factors), the supplier is responsible for free repairs, and the required replacements are provided by the buyer free of charge (except consumable parts). After the warranty period, only the actual maintenance cost will be charged for maintenance.5. Packaging and transportation: The supplier meets the domestic railway or highway transportation packaging standards on the packaging. It is suitable for long-distance bus transportation or train transportation. It is moisture-proof, rust-proof, shock-proof and rough-proof loading and unloading, suitable for overall lifting. Each part of the equipment is packed according to relevant standards, and each packing box has a detailed packing list.VII. The Exhibition Photos:

You may also like

Send inquiry

Send now