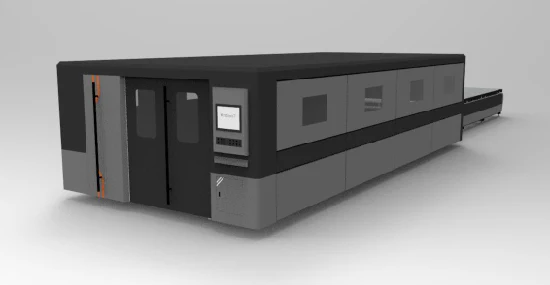

Big Power Fiber Laser Cleaning Machine for Car Mold Welding Trace Clean Remove

Basic Info

| Model NO. | CKD-PLFC-1000/1500, V19.10 |

| Control System | 13 Languages |

| Control Box | with Wheel, Easy to Move |

| Fiber Cable | 8 Meters |

| Transport Package | Wooden Case |

| Specification | Asia/Europe/America Standard |

| Trademark | CKD LASER |

| Origin | Shenzhen, China |

| HS Code | 8486204900 |

| Production Capacity | 20 Set/Month |

Product Description

LASER CLEANING MACHINE FOR RUST DUST REMOVE/SKIN PEELING/SURFACE REPAIR

APPLICATION OF LASER CLEANING MACHINE

Laser cleaning has the characteristics of non-grinding and non-contact. It can not only be used to clean organic pollutants, but also inorganic substances, including metal corrosion, metal particles, dust, etc.

(1) Non-contact cleaning, no damage to under layer of workpiece.

(2) Easy to operate, aim the gun to material, press the trigger to shot laser.

(3) Precision positioning, selective cleaning.

(4) No need chemical detergent, no consumable. Safe and Environment-friendly.

(5) High cleaning efficiency, time-saving.

(6) Stable laser cleaning system, free maintenance.

Laser cleaning machine can be used in industries of aviation, ship, cultural relic protection, car week, food, track, rubber mold and so on.

With mini laser gun, only 0.7Kg, reduce the burden on operators.

With 8 meter long fiber cable, laser cabinet is with wheels, easy to move around, flexible operation.

With double LED focus tools, it's right focus when the overlap, then press the triggers to shot laser.

With air nozzle to blow away dust during cleaning.

With supporter to avoid fiber cable to be bent too much, keep the fiber cable saftey.

With coiled shaft on the top of the machine, which is convenient to collect fiber cable when don't use.

Built-in water chiller inside the machine, avoid dust pollution and free from installation.

COMPARISION LASER CLEANING TO OTHERS

Compared with other cleaning methods, laser cleaning has significant advantages:

Comparison item | Chemical cleaning | Mechanical polishing | Dry ice cleaning | Ultrasonic cleaning | Laser cleaning |

Cleaning method | Chemical cleaning agent | Mechanical/sandpaper, contact type | Dry ice, non-contact | Cleaning agent,contact type | Laser, non-contact |

Workpiece damage | Damaged | Damaged | No damage | No damage | No damage |

Cleaning efficiency | Low | Low | Middle | Middle | High |

Cleaning effect | Generally, uneven | Generally, uneven | Excellent, uneven | Excellent, small clean area | Very good and clean |

Cleaning accuracy | Uncontrollable,poor accuracy | Uncontrollable,average precision | Uncontrollable, poor accuracy | Cannot be cleaned within specified range | Precise and controllable,high precision |

Safety/environmental protection | Serious chemical pollution | Polluted environment | No pollution | No pollution | No pollution |

Manual operation | The process is complicated and requires high requirements for operators, and protective measures are needed | Strong physical strength, need safety protection measures | Simple operation, handheld or automated | Simple operation, but need to manually add consumables | Simple operation,handheld or integrated automation |

Supplies | Chemical cleaning agent | Sandpaper, grinding wheel, oil stone, etc. | Dry ice | Special cleaning fluid | Only power supply |

Cost input | Low initial investment,high cost of consumables | High initial investment andhigh labor cost forconsumables | Medium initial investment, high cost of consumables | Low initial investment,medium cost of consumables | High initial investment, no consumables,low maintenance cost |

THECH DATA OF CKD-PLCF

Low Power | High Power | ||||||||

Type of machine | CKD-PLFC -20 | CKD-PLFC-30 | CKD-PLFC-50 | CKD-PLFC -60 | CKD-PLFC-70 | CKD-PLFC-80 | CKD-PLFC-100 | CKD-PLFC -1000 | CKD-PLFC -1500 |

Power of laser source | 20W | 30W | 50W | 60 | 70 | 80 | 100 | 1000W | 1500W |

Laser wavelength | 1064nm | 1080±5 | |||||||

cooling method | Air-cooling | Water-cooling | |||||||

Cooling water | -- | Deionized water | |||||||

Water temperature | -- | 19ºC | |||||||

Washing head weight | 4.5KG | 0.75KG | |||||||

Total Weight | 27KG | 260KG | |||||||

Total power | ≤500W | ≤2000W | |||||||

Scan width | 10-80mm | ||||||||

Operating temperature | 15ºC-35ºC | ||||||||

Remark: laser power under 100W is customized type. Recommend 1500W as priority choice for high efficiency laser clearning. | |||||||||

CONFIGURATION OF 1000W AND 1500W

Operating mode | Continuous/Modulation | |

Type | CKD-PLFC-1000 | CKD-PLFC-1500 |

Power of laser source (W) | 1000 | 1500 |

Laser wavelength (nm) | 1080±5 | |

Beam quality (M2) | <1.4 | |

Power adjustable range (%) | 5-100 | |

Fiber cable (m) | 8m | |

Cooling modle | Water cooling | |

Working temperature (ºC) | 15-35 | |

Focal length (mm) | 350 | |

Cleaning scope (mm) | 1-50 | |

Whole machine power (Kwh) | <7KW | <7.5KW |

Working temperature | 5ºC-40ºC | |

Relative humidity | 90%No condensation | |

Surroundings | Ventilated, no impact within 5 meters | |

Electricity | 220V±5%, 50Hz | |