5% 1000W 1500W 2000W Dealer Price 3 Functions Laser Welding Machine Handheld Laser Cutter

Basic Info

| Model NO. | LMH2000 |

| Warranty | 3 Years |

| Model | Lnh2000 |

| Fiber Cable Line | 10m |

| Wavelength | 1070±10nm |

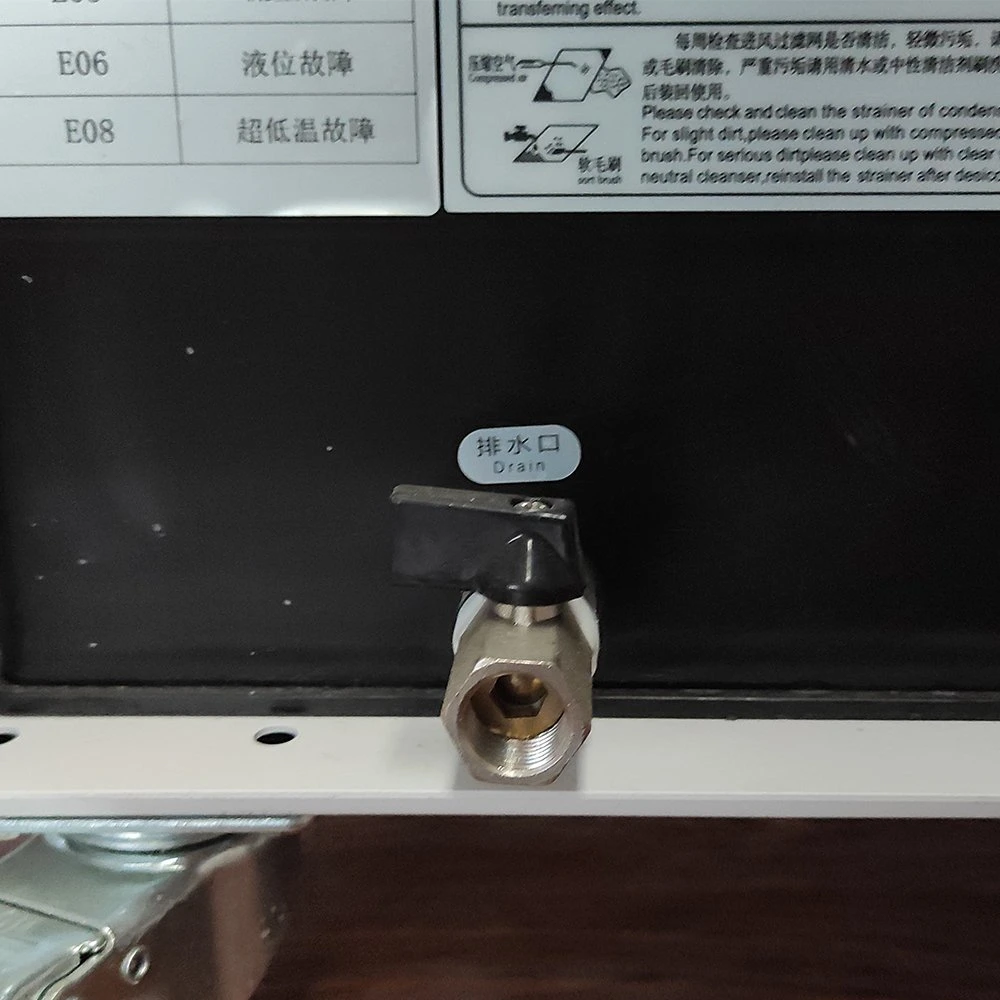

| Cooling Method | Water Cooling |

| Working Environment | -20-40ºC |

| Laser Clean Gun | China Top Brand |

| Focus Length | 400mm |

| Swing Frequency | 150kHz |

| Cleaning Head Weight | 1.2kg |

| Connection | Qbh |

| The Monitor with Various Language | Chinese, English, Russian, Spanish Can Customized |

| Total Power | 5.12kw |

| Package | Wooden Box for Export |

| Package Size | 138*86*146cm |

| Package Weight | 149kg |

| Transport Package | Wooden Case |

| Specification | 138*86*146cm |

| Trademark | Laser Max |

| Origin | China |

| HS Code | 845611 |

| Production Capacity | 1000sets/Year |

Packaging & Delivery

Package size per unit product 138.00cm * 86.00cm * 146.00cm Gross weight per unit product 149.000kgProduct Description

The laser cleaning machine produced by Laser Max Laser is a new generation of high-tech products for surface cleaning, thin metal welding and cutting. It is very easy to install and operate. The machine needs no chemical reagent, no medium, dust-free and water-free cleaning, with the advantages of automatic focus, crank surface cleaning and high surface cleanliness.Laser cleaning machine can remove the object surface resin, the paint, the oil pollution, Stains, dirt, rust, coatings, coatings and oxide coatings are widely used in the industry, covering ships, steam repairs, rubber molds, high-end machine tools, track and environmental protection.

Features:

1. Fast and concentrated pulses with enormous power impact and gasification of residues on the surface;2. Laser pulses are very suitable for the removal of organic matter, such as residues in the tire mold fouling;3. The impact of a short period of time will not cause metal surface heating, no damage to the substrate.4. Clean or remove the surface paint layer quickly and cleanly;5. Accurate cleaning and paint removal effect;6. No damage to the base material;

1. High speed, large depth and small deformation.2. It can be welded at room temperature or under special conditions, and the welding equipment is simple. For example, if a laser passes through an electromagnetic field, the beam will not shift; Laser can weld in vacuum, air and some gas environment, and can weld through glass or materials with transparent beam.3. It can weld refractory materials such as titanium, quartz, etc., and can weld dissimilar materials with good results.4. After laser focusing, the power density is high. When welding high-power devices, the depth width ratio can reach 5:1, and the maximum can reach 10:1.5. Micro welding is possible. After focusing, the laser beam can obtain very small light spot, and can be accurately positioned, which can be applied to the assembly welding of micro and small workpieces in mass automatic production. (The minimum facula can reach 0.1mm)6. It can be used to weld parts that are difficult to access. It is very flexible to perform non-contact remote welding. Especially in recent years, fiber transmission technology has been used in YAG laser processing technology, and the popularity of fiber continuous laser has made laser welding technology more widely promoted and applied, which is more convenient for automatic integration.7. The laser beam can easily realize the beam splitting according to time and space, and can be processed simultaneously by multiple beams and multiple stations, providing conditions for more precise welding.

| Model | LMH2000 |

| Power | 2000W |

| Max welding | 3mm |

| Fiber Cable Line | 10m |

| Wavelength | 1070±10nm |

| Working environment | -20-40ºC |

| laser clean gun | China top brand |

| Focus Length | 400mm |

| Swing Frequency | 150KHZ |

| Cleaning Head Weight | 1.2kg |

| Working power | 220V |

| Cutting thickness | 1mm |

| Original | Shandong |